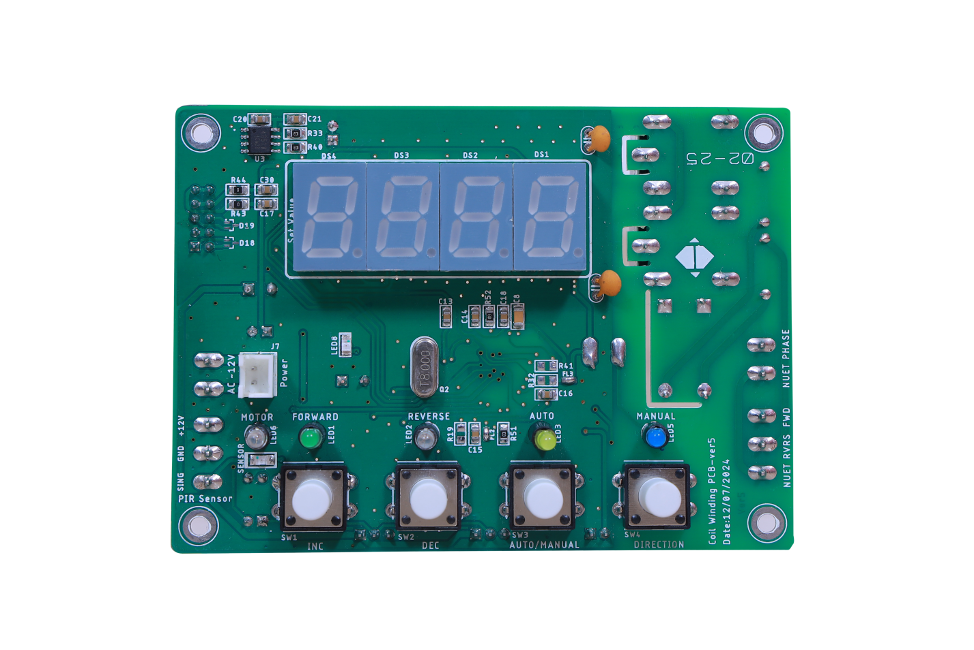

Coil Winding Controller

Coil winding is the process of wrapping a conductive wire, typically copper or aluminum, into a coil shape. This is commonly done to produce inductors, electromagnets, transformers, motors, and various electrical components.

Imagine neatly wrapping a long wire around a spool, core, or frame to create a coil. The number of turns, wire thickness, and winding pattern all influence the electrical and magnetic properties of the coil.

Pain Points of Manual Coil Winding Machine for Fan Bore Winding

- Inconsistent Turn Count

- Number of turns of copper wire is the key process in the winding.

- In a manual winding machine, manual error may produce wrong counts, resulting in excess of copper or low count, which directly affects the motor’s efficiency and performance.

- Poor Alignment Quality

- Manual process often results in no clean alignment of the copper wire.

- Uneven winding increases resistance, creates hotspots, and can lead to premature coil failure.

- Operator Fatigue & Low Productivity

- Manual winding is time-consuming and physically tiring, leading to slow production rates and inconsistent output.

- High Skill Dependency

- Quality depends heavily on the operator’s skill and experience, making training and retention a challenge.

- Higher Material Wastage

- Inaccurate counts and improper wire handling cause copper wastage, increasing production costs.

Automatic Coil Winding Machine Performance

- Precision in Turn Count

- Automatic control ensures accurate number of turns of copper wire every time, eliminating excess or shortage of turns.

- Perfect Wire Alignment

- Mechanized layering ensures clean and uniform winding, improving coil quality, efficiency, and motor life.

- Increased Productivity

- High-speed automatic operation significantly reduces winding time, enabling mass production without compromising quality.

- Reduced Skill Dependency

- Operators only need to set parameters; winding consistency is maintained regardless of skill level.

- Minimal Material Wastage

- Precise control over winding length and turns optimizes copper usage and reduces scrap.

- Consistent Quality Output

- Every coil meets the same standard, ensuring reliable motor performance and fewer rejections

Key points about coil winding:

- Purpose – When current flows through a conductor, it generates a magnetic field or stores energy in the magnetic field.

- Materials – Copper wire is typically coated with enamel insulation.

- Cores – The wire can be wound around different materials like air, ferrite, laminated steel, or others to improve magnetic properties.

- Applications – Used in transformers, electric motors, inductors, solenoids, sensors, and speakers.

- Techniques – It can be wound manually for small tasks or with automatic coil winding machines for precise and mass production.

Why Choose Us

At KFTRONICS, we have over a decade of experience in designing and manufacturing high-quality coil winding PCBs for various industrial applications. Our commitment to precision, performance, and reliability has earned us the trust of our customers.

Here’s why industries choose us:

- 10+ Years of Proven Experience

With a decade of experience in the field, we have acquired extensive technical knowledge and practical expertise to provide PCB solutions that adhere to global quality standards. - Specialized in Coil Winding Technology

Our in-house team recognizes the crucial role of coil winding in PCB performance. We focus on achieving perfect winding patterns, minimizing losses, and maximizing efficiency. - Premium Quality Materials

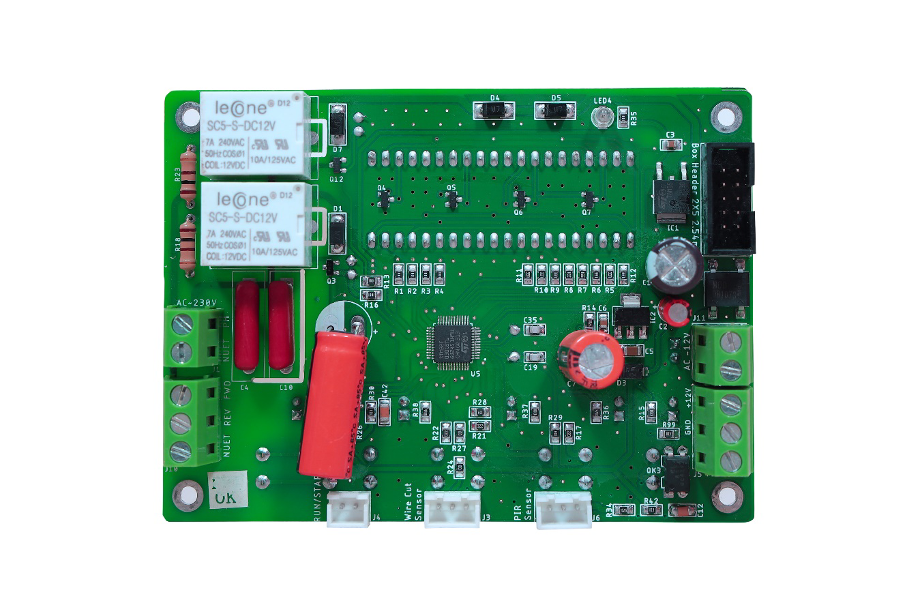

We use high-quality copper wire, durable PCB laminates, and advanced insulation coatings to ensure reliable and long-lasting performance. - Advanced Manufacturing Facilities

Our facility is equipped with state-of-the-art winding machines and precision soldering systems, ensuring strict quality control at every stage. - Custom Solutions for Every Need

We specialize in designing and manufacturing custom coil winding PCBs to meet your specific requirements and application needs, from prototype to mass production. - Reliability You Can Trust

Every PCB undergoes thorough testing to ensure durability, performance, and safety, even in challenging environments. - Global Client Satisfaction

Our products are used in a wide range of industries, such as electronics, automotive, textile machinery, and industrial automation, and are trusted by customers worldwide.

Advantages of Choosing KFTRONICS

- Decade of Expertise

With over 10 years of experience in the industry, we offer extensive technical expertise and established manufacturing practices. - Precision Engineering

Our advanced coil winding techniques guarantee consistent turns, low resistance, and optimal efficiency. - High-Quality Materials

We use high-quality copper wire, durable PCB laminates, and premium insulation for reliable and long-lasting performance. - State-of-the-Art Facilities

We have modern winding machines and precision testing equipment to ensure consistent quality. - Custom Design Capability

We specialize in designing and manufacturing custom PCBs to meet your specific requirements, from prototypes to large-scale production orders. - Strict Quality Control

Each PCB undergoes a thorough multi-stage inspection process to ensure compliance with international standards and client specifications. - Reliable Global Supply

Trusted globally for on-time delivery and reliable performance.