Electronic Jacquard Machine

An Electronic Jacquard Machine is a modern textile weaving device that automates the intricate process of controlling individual warp threads to create complex woven patterns, using electronic control instead of the traditional mechanical punch card system.

Key Features:

- Electronic Control Unit:

- Replaces traditional punched cards with digital memory and software.

- Stores multiple designs that can be easily selected or modified.

- Solenoids or Actuators:

- Control the lifting and lowering of individual warp threads.

- Enables the creation of highly complex and varied textile patterns.

- Integration with Looms:

- Can be mounted on power looms or shuttle less looms.

- Works in synchronization with the loom's weaving mechanism.

- Design Software Compatibility:

- Designs can be created using CAD (Computer-Aided Design) software.

- Patterns are uploaded directly to the machine.

Advantages over Traditional Jacquard Machines:

| Feature | Traditional Jacquard | Electronic Jacquard |

| Pattern Storage | Physical punch cards | Digital memory |

| Pattern Switching | Manual | Automatic |

| Speed & Efficiency | Slower | Faster |

| Design Complexity | Limited | High |

Applications:

- Sarees, brocades, and other decorative fabrics

- Home textiles like curtains and upholstery

- Industrial textiles and fashion apparel

In short, an Electronic Jacquard Machine brings digital precision and flexibility to textile weaving.

Are You Considering Purchasing an Electronic Jacquard Machine? Make Sure You Are Aware of These Three Key Factors Before Making Your Decision!

- Mechanical Body

- M5 Module

- Electronics Jacquard Controller

Mechanical Body

- The heavier the machine on the loom, the longer its lifespan.

- If the electronic jacquard machine is too heavy, it can reduce the vibration of the loom, causing needle drop issues.

- If the weight of the electronic jacquard machine is too light for the loom to operate, it may lead to needle issues and increased chances of malfunctions.

- First, check if the center shaft has a double ball bearing and identify the brand of the company. Ensure that the brand is reputable and known for quality products.

- The M5 module punching knife should be able to move 0.5mm. If the knife does not move, the module will be damaged.

M5 Module:

If you’re referring to a Jacquard weaving context and you saw “M5 Module”, it could potentially mean a module or unit used in modern Jacquard electronic control systems, possibly model M5 from a specific manufacturer (e.g., S&S, YGMS, or Excellent). In that case:

The S&S M5 module is commonly used in electronic jacquard machines due to its compact design, low power consumption, and high reliability. It features a sealed, low-power electromagnet, durable harness cords, and long-lasting pulleys. The module offers choices between bearing and non-bearing pulleys and can be tailored for different loom types such as rapier, air jet, water jet, shuttle, and projectile looms.

Mechanical Body

Key Features:

Low Power Consumption:

- The sealed, low-power electromagnet helps save energy and ensures efficient operation.

Durable Components:

- Durable harness cords and pulleys with high wear and corrosion resistance improve the module’s longevity.

Versatile Application:

- The M5 module is compatible with different types of looms, such as Hand Loom, Power Loom, Rapier Loom, Auto Loom, and projectile mechanisms.

Customization Options:

- Users can select pulleys with or without bearings for customized jacquard weaving applications.

Compact Design:

- The module is compact, making it ideal for weaving machines with limited space.

Reliability:

- The module’s stability and reliability are enhanced by features such as a one-piece honeycomb structure and an elastic diaphragm.

Electronics Jacquard Controller

- Electronics are essential components in a jacquard machine.

- When purchasing an electronic jacquard machine, verify if the manufacturer produces the electronics in-house or sources them externally.

- Those who own their products have quick access to spare parts and service.

- If you purchase an electronic jacquard machine from a middleman, you may encounter difficulties in obtaining service and spare parts.

- Middlemen do not always purchase electronics from the same seller.

- If you purchase an electronic jacquard machine from a dealer and later discover that a small piece of software is missing, you can easily obtain it from the manufacturer for a nominal fee of 200 to 500 rupees after a year or two. However, middlemen may not have this knowledge and may pressure you into purchasing a completely new set of electronics. They may exaggerate the cost of a simple fix, claiming it will cost tens of thousands of rupees, when in reality it could be resolved for a much lower amount.

- Check for gold-plated electronics.

When to Use Gold Coating

- High-reliability signal contacts (low voltage/current).

- Frequent connect/disconnect cycles.

- Harsh or corrosive environments.

- Where long-term low contact resistance is critical.

- Premium or mission-critical electronics.

When to Use Tin Coating

- General-purpose cost-effective connections.

- Power connections where slight oxidation is acceptable.

- Soldered joints, PCB tracks, standard terminals.

- Applications with fewer mating cycles.

Key Trade-off

- Gold = Performance, Reliability, Costly

- Tin = Economical, Sufficient for general use, but needs good design to avoid corrosion or oxidation problems

Gold Coating vs. Tin Coating — Comparison

Feature | Gold Coating | Tin Coating |

Material | Thin layer of pure gold (often 0.1–2.5 µm) | Thin layer of pure tin (or tin alloy) |

Corrosion Resistance | Excellent — gold is inert, does not oxidize | Good — tin resists corrosion but can oxidize over time |

Conductivity | Very high — gold maintains low contact resistance | Good — tin is conductive but can form oxide layers that increase resistance |

Durability (Fretting & Wear) | Excellent for frequent mating/unmating — hard gold plating resists wear | Good for low mating cycles, oxide layer can wear off |

Solder ability | Not typically soldered — gold must be removed first due to solder embrittlement | Very solder able — tin is widely used as a solder finish |

Contact Reliability | Highly reliable in harsh or low-current signal applications | Reliable for moderate currents, but contact resistance can increase if oxide builds up |

Cost | High — gold is expensive | Low — tin is cheaper, common for cost-sensitive products |

Electronics Jacquard Controller

Example for Jacquard Controllers:

- For signal connectors (data lines), gold coating gives better long-term performance and reliability, especially in dusty/weaving shed environments.

- For large power connectors or terminal blocks that are soldered once, tin coating is practical and cost-effective.

Why Choose Us

KFTRONICS is a reputable company in the textile industry, known for designing and manufacturing high-performance electronic Jacquard controllers. With over a decade of experience, we provide reliable and advanced control solutions to weaving units, power looms, and textile innovators, enabling them to achieve precision, efficiency, and quality in their weaving processes.

Established in 2015, KFTRONICS aims to democratize Jacquard technology by offering cost-effective solutions to weavers of all sizes. With a strong focus on R&D, stringent quality control, and excellent customer service, we have become a trusted manufacturer in the industry.

Our controllers power numerous Jacquard machines in India and beyond, enabling our customers to remain competitive in a changing market. We continuously enhance our products to align with evolving weaving trends, increased needle counts, and advanced automation requirements.

Today, our controllers power thousands of Jacquard machines across India and beyond, helping our customers stay competitive in an evolving market. We constantly upgrade our products to keep pace with new weaving trends, higher needle counts, and smarter automation demands.

Our Strengths:

- 10 years of proven expertise in electronic Jacquard control technology.

- In-house design and manufacturing for consistent quality.

- Prompt technical support and service backup.

- Continuous innovation to meet modern weaving challenges.

- A strong network of dealers and partners who trust our brand.

At KFTRONICS, we are dedicated to helping our customers grow. Whether you operate a single loom or a full weaving shed, our goal is to provide solutions that boost productivity, minimize downtime, and safeguard your long-term investment.

Our Features:

- Free RTOS – Advanced ARM 32-bit electronic controller.

- User Friendly graphical user interface.

- Format support: BMP and Encrypted.Txt-Conversion.

- 64GB External USB support.

- Built-in 32GB SD card.

- 2″ color TFT graphical display.

- Hook capacity: 32 to 7616.

- Hook Position. ( Front Right / Back Left )

- Independent body and border design.

- Pick lock system for distributor.

- Applicable for: Hand loom, power loom, rapier loom, Auto Looms, SOMET, and PICANOL.

- Encrypted .Txt format will protect design files.

- Dual Sensor Concept: Supports both Knife and Collar Type.

- First Hook: We can position the Hooks for the front right or the back left.

- Hardware testing includes communication and self-tests.

- The built-in test pattern includes all down, all up, 1*1, and 2*2.

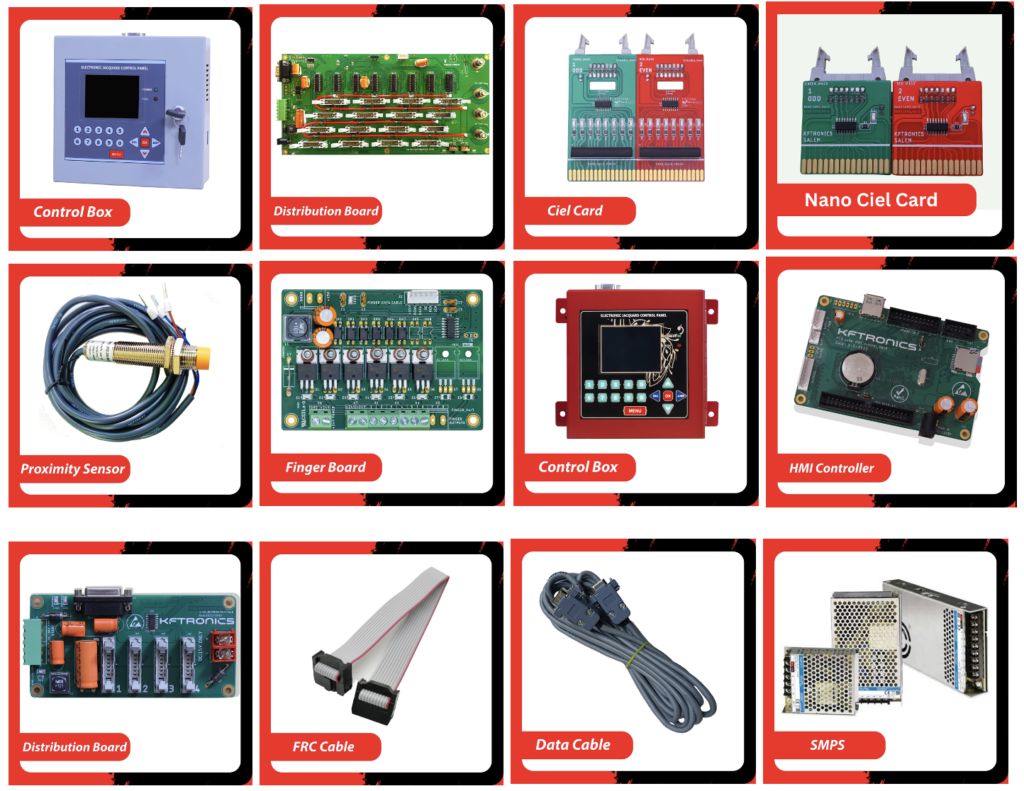

List of Accessories Included In Electronic Jacquard Controllers:

- 2” Colorful TFT Graphical Display

- Mother Board / Distribution Board / CICO Board

- Ciel Cards / CL Cards / M5 Driver Cards

- Flat Ribbon Cable (FRC)

- Proximity Sensor

- Meanwell SMPS

- Data Cables

- 32GB SD Card

- Color Selector / Finger Board for Rapier Loom,

- Power Panel Box.