Mechanical Design Services

We Covers every aspect of the product design process including industrial design/sketches, 3D CAD design, CMF (colour, material and fitment) design, 2D drawings, simulation, 3D prototype validation, DFM analysis and drawing update, tooling and final production. We turn your Innovative ideas into initial sketches to visualize what the final product might look like. Once you are happy with the shape, you can design using a 3D CAD program such as Solid Works, Creo Parametric 3D Modeling Software or other tools to ensure the product is feasible for both the user and the manufacturer.

At KFTRONICS, our Mechanical CAD Designing services are at the forefront of innovation, precision, and efficiency. Our team of experienced engineer’s leverages advanced CAD tools and methodologies to deliver comprehensive solutions tailored to your complex mechanical design needs. Whether you’re developing intricate machinery, reverse-engineering components, or validating concepts, we provide end-to-end support to ensure your project’s success.

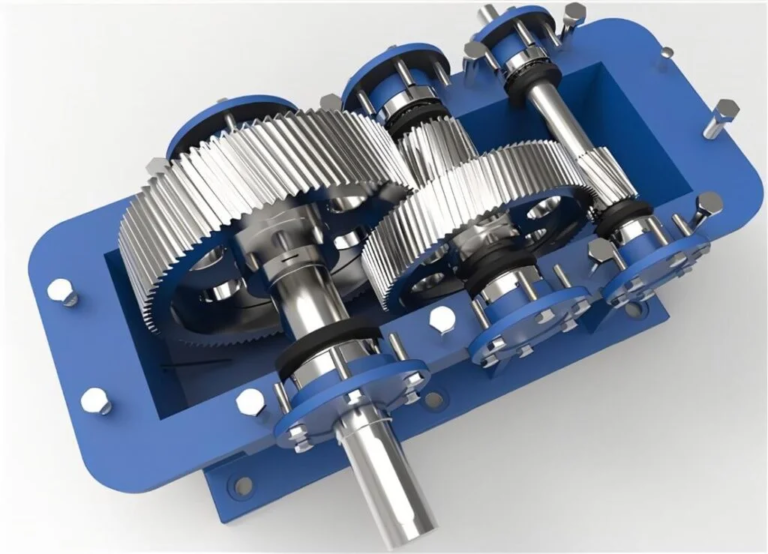

Complex Machine Design

Designing complex machinery requires a deep understanding of mechanical principles and a keen eye for detail. At KFTRONICS, we excel in creating intricate machine designs that meet rigorous performance standards and operational requirements.

- Detailed Design: We produce highly detailed CAD models and engineering drawings that capture every aspect of your machine’s design, from component integration to assembly procedures.

- Functional Analysis: Our team performs thorough analyses to ensure that each design meets functional requirements and operates efficiently within its intended environment.

- Optimization: We apply optimization techniques to enhance performance, reduce material usage, and ensure cost-effective manufacturing processes.

Reverse Engineering Part Design

Reverse engineering is a crucial process for replicating and improving existing components. KFTRONICS provides expert reverse engineering services to recreate and enhance parts with precision and accuracy.

- 3D Scanning and Analysis: We use advanced 3D scanning technology to capture detailed measurements and geometries of existing parts, facilitating accurate digital reconstruction.

- Reproduction and Enhancement: Our team redesigns parts based on scanned data, improving upon original designs to meet new specifications or enhance performance.

- Documentation: We produce comprehensive 2D drawings and 3D models that facilitate manufacturing and integration of reverse-engineered components.

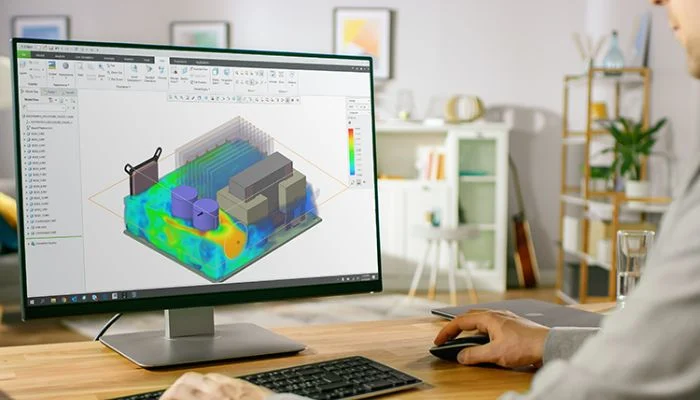

2D Drawing and 3D Simulation

Accurate 2D drawings and 3D simulations are essential for effective design and verification. At KFTRONICS, we create detailed 2D technical drawings and perform advanced 3D simulations to visualize and test designs before production.

- 2D Technical Drawings: Our 2D drawings include all necessary dimensions, annotations, and specifications to support manufacturing and assembly processes.

- 3D Simulation and Analysis: We utilize 3D simulation tools to evaluate design performance, conduct stress analysis, and predict potential issues, ensuring designs meet all functional and safety requirements.

Proof of Concept

Validating the feasibility of a design concept is crucial for successful project execution. KFTRONICS offers proof-of-concept services to demonstrate the viability of your ideas and ensure they meet your objectives.

- Concept Development: We work closely with you to develop initial concepts and translate them into detailed CAD models and simulations.

- Prototype Testing: We design and build prototypes to test and validate design concepts under real-world conditions, providing valuable insights for further refinement.

- Feasibility Assessment: Our team conducts thorough assessments to evaluate the practicality and potential of your concept, identifying any necessary adjustments before full-scale development.

At KFTRONICS, our Mechanical CAD Designing services are designed to address the most demanding challenges in machine design and part development. With our expertise and cutting-edge technology, we transform complex ideas into reality, ensuring precision, efficiency, and excellence.

Industrial design and sketching

Our teams are experts in the creation of innovative industrial designs that combine functionality with design aesthetics. From preliminary sketches to detailed renderings, we bring your product ideas to life.

CMF (color, material and fitment) design

To ensure your product matches your brand identity and user expectations, we pay close attention to colour schemes, material selection and fitment.

Technical Documentation and 2D Drawings

Essential to manufacturing are clear and accurate 2D drawings. We provide detailed technical documentation including how to assemble, part specifications and tolerances.

Simulation and validation of products

To evaluate product performance under different conditions, our team conducts simulation tests. This helps to ensure reliability, safety and optimum functionality.

Design for Manufacturing (DFM) analysis

For efficient and cost-effective manufacturing processes, we analyze designs to optimize them. Our aim is to minimize production challenges and improve quality.

Tooling and Finishing

We work closely with tooling experts to create the moulds, dies and fixtures required for production. Our end-to-end support ensures a smooth transition from design to production.

Why Choose Us?

A proven track record: Our successful projects speak for themselves.

Innovation: We keep at the forefront of design methods.

Our market share: Understanding of market dynamics and alignment of our designs accordingly.

ESG ratings: Our commitment to environmental, social and governance factors sets us apart.

We invite you to explore our website. You will find more details about our services and case studies. If you have any specific requirements, Contact us today to discuss your Mechanical CAD Designing needs and explore how we can support your next project with our comprehensive services