Schematic Capture

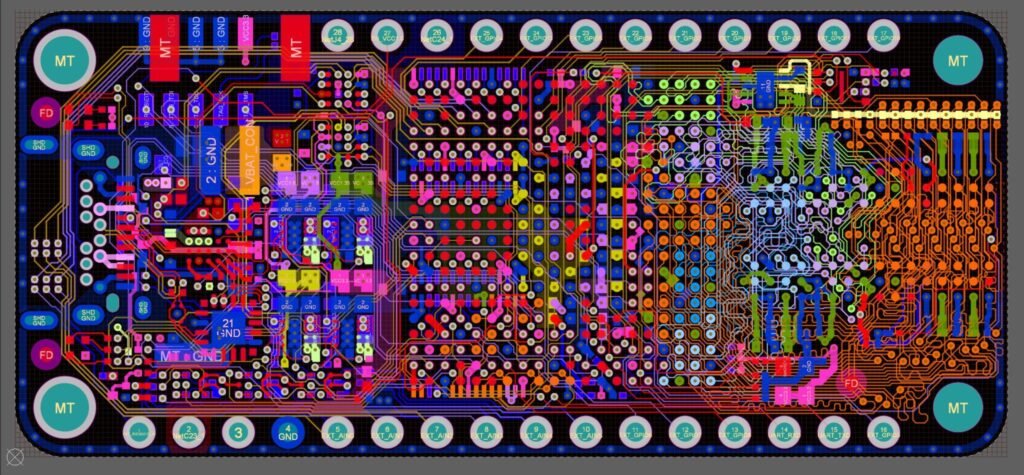

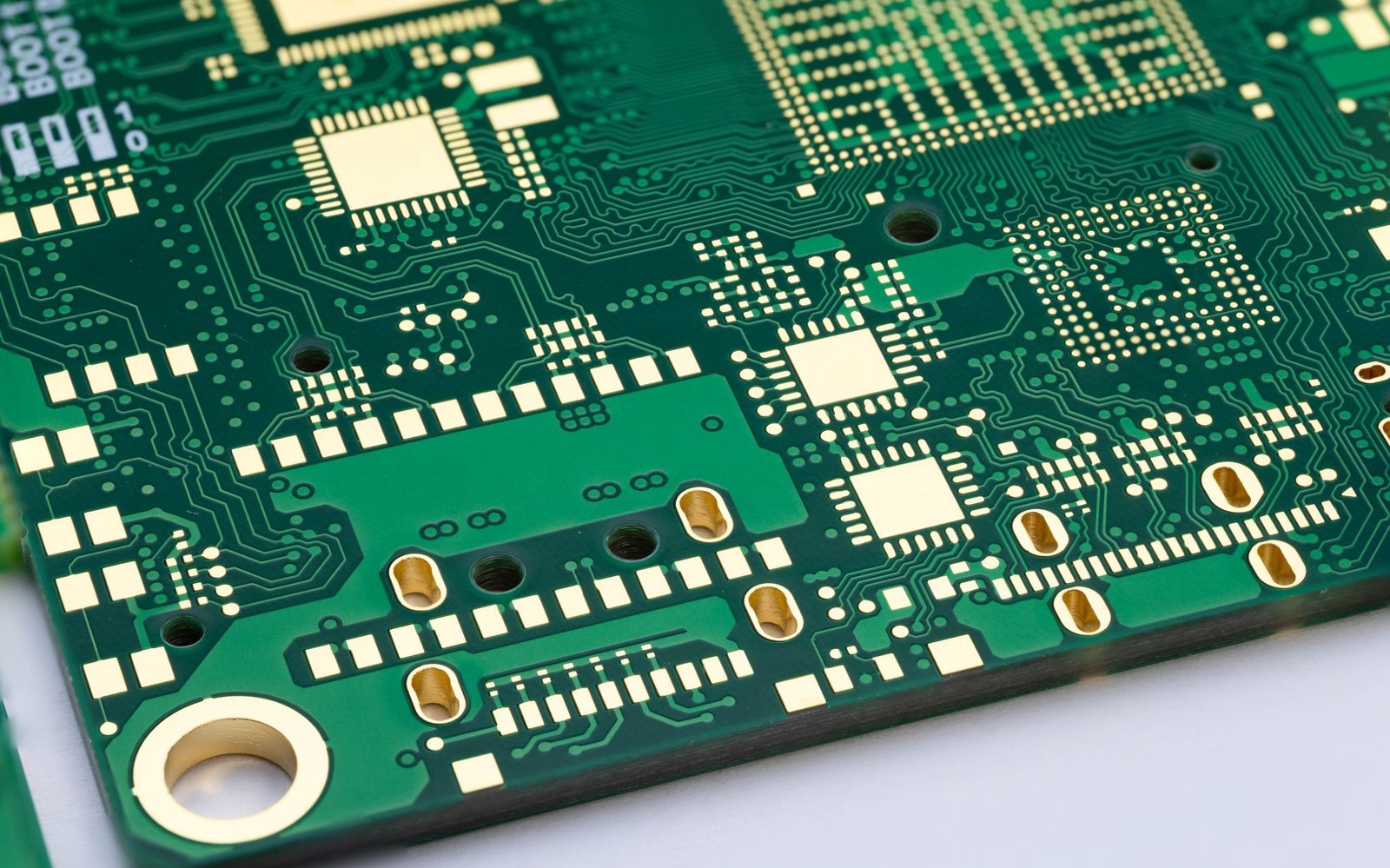

Schematic design is essential for any project, serving as the basis for construction plans and electronic circuits. This guide explores the key principles and elements of schematic design, providing you with the necessary knowledge to navigate this critical stage. It transforms initial ideas and needs into a visual representation, defining the project’s form, function, and spatial relationships. In essence, it acts as a roadmap for the project’s progression.PCB Layout: